|

RB Starnberg – Roland Mayerhofer RB Starnberg – Roland Mayerhofer Glass and other brittle, transparent materials offer unique properties,that will fuel a continously growing use in consumer electronics, medical devices, integrated circuits, architectural,automotive, aerospace and a variety of other interesting market segments. Due to low absorption for solid-state lasers and typically a low thermal-shock resistance, it has always been challenging to find suitable laser processes to cut glass and other transparent and brittle materials in a fast and precise way. Through a recently completed asset deal, ROFIN acquired all the published and filed IP, the know-how,the lab equipment and the customer base of the company FiLaser USA LLC. We are also very happy to welcome the mastermind behind that outstanding technology development,Dr. Abbas Hosseini, as a new member within the ROFIN organization. ROFIN is now able to provide the widest range of high-quality laser cutting processes for strengthened and non-strengthened glass, sapphire and ceramics in the world. Beside the successfully established fusion cutting technology using the LFS-laser of ROFIN-Lasag especially for sapphire and ceramics (ROFIN SmartCut™FC) as well as the option to perform an ablation cut through thin brittle materials by ROFIN pico- or femtosecond lasers (ROFIN SmartCut™AC), this newly acquired technology opens the door to a much wider application area, especially but not at all limited to the consumer electronics area. This new process is called ROFIN SmartCleave™ FI and is utilizing dedicated ultra-short pulsed lasers with unique properties in burst mode operation. The base technology is patented (as well as patent pending) and using a line of so-called filaments to separate brittle and transparent materials in a high-speed, debris-free and quasi zero-gap process.

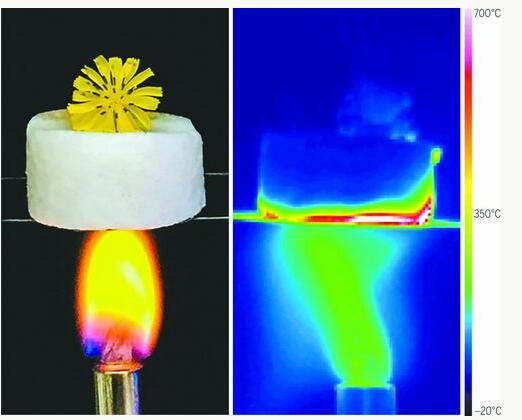

The ROFIN SmartCleave™FI process allows cutting arbitrary shapes including small radii of down to 2 mm in a single pass without taper. The resulting surface finish is basically free of chipping. Typical surface roughness values ra of less than one micron lead to high bending strengths of the cut parts. At sufficient internal stress levels, like present in chemically or thermally strengthened glass, the filamented material is separating automatically. Non-strengthened glass or ceramics can easily be separated by low mechanical or thermal force, the latter can, for example, be provided by a CO2-laser heating process. The new ROFIN SmartCleave™FI process will provide a smart way to cut long and labor-intensive mechanical processing chains down to only a few process steps. At processing speeds of several hundreds of millimeters, glass and other transparent brittle materials can be filamented in a single pass up to a typical thickness of 2 mm, thicker cross sections even up to 8 mm can be separated by applying a multi-pass process. The field of applications for the new ROFIN SmartCleave™FI technology is vast and, amongst many others, comprises mobile phone displays made out of strengthened and non-strengthened glass as well as sapphire, television or computer and tablet displays, LED and OLED products and other microelectronic applications,glass substrates for integrated circuits, optics, watches, architectural and household glass, medical devices,semiconductors or ceramics. Today, many laser or equipment suppliers pretend to have a viable glass cutting solution, but there is barely a company in the market that can cut strengthened as well as nonstrengthened glass or sapphire into arbitrary shapes with small radii and cut-out features at comparably high speed and quality as the ROFIN SmartCleave™FI process. Leading glass manufacturers have already confirmed, that this is an outstanding technology, that offers great potential to substitute conventional manufacturing processes.

Two dedicated application labs, one at ROFIN-BAASEL Lasertech, Starnberg,and the other one established at LEE Laser, Orlando, USA, will provide worldwide application support.Depending on customer requirements,the substrate size or other specific arrangements, ROFIN will offer lab systems, complete processing workstations or integration packages,always including a process license,to customers and integrators. |

收藏

收藏 打印

打印